2021/10/28/ · Supplies were the leading class of pharmaceuticals with an overall wastage rate of 37.1%. AOR = 4.34), writing label (P value = 0.02, AOR = 5.04), storage of segregated waste in dispensing unit (P value = 0.01, AOR = 0.72) and the presence of disposal plan (P value = 0.002, AOR = 16.93). ... It will also help policymakers for

2020/7/29/ · The fermentation was done using initial reducing sugars concentration of 40 g/L in the medium at pH 5.5, 150 rpm and 30 °C for 30 h and ethanol production was estimated at every 6 h. The fermentation medium was sterilized by autoclaving at 121 °C for 15 min, cooled and inoculated with 24 h old seed culture (5% v/v) of S. cerevisiae. One

2020/8/1/ · Effect of solid waste fermentation substrate on wheat (Triticum aestivum L.) the proper reuse of the fermentation substrate could reduce the use of inorganic salts by 9.8%-11.9% and save 40L ... Solid waste treatment unit is a crucial component in BLSS for recycling substrates. Solid waste treatment and recycle are

2024/3/1/ · Providing reducing power to the fermentation system may facilitate the lactic acid fermentation process. Xue et al. (2018) introduced the electrochemical system into the lactic acid fermentation system and found that the application of −100 mV voltage increased the yield of lactic acid by 4.73 times, improved the optical purity of l -Lactic

2023/11/28/ · The growing concern about the availability of safe and sustainable natural food supplies is a direct result of a rapidly expanding global population (Knorr and Augustin 2022).For the production of the next generation of food components and products, fermentation stands out among other approaches like cellular or acellular products,

This work aimed to couple lactate production and subsequent chain elongation to decrease chemicals input such as electron donors and hydroxide for pH control in repeated-batch food waste fermentation. Food waste with adjusted pH was used as substrate and fermentation proceeded without pH control.

2019/7/16/ · Many of today’s commercial biological products are produced by microorganisms via fermentation processes. Microbial fermentation allows us to scale-up the production, by utilizing a large quantity of microbial cells to generate the product of interest in a controlled fermentation process [].Besides, the use of microorganism as a

2024/3/15/ · The VFAs concentration in the anaerobic fermentation of kitchen waste was predicted with an improved deep belief network which employs the average flow rate, total solids (TS), pH, volatile solids (VS), alkalinity, the daily biogas, the content percentage of CO 2, and the content percentage of CH 4 as model inputs (Wang and Li, 2019).

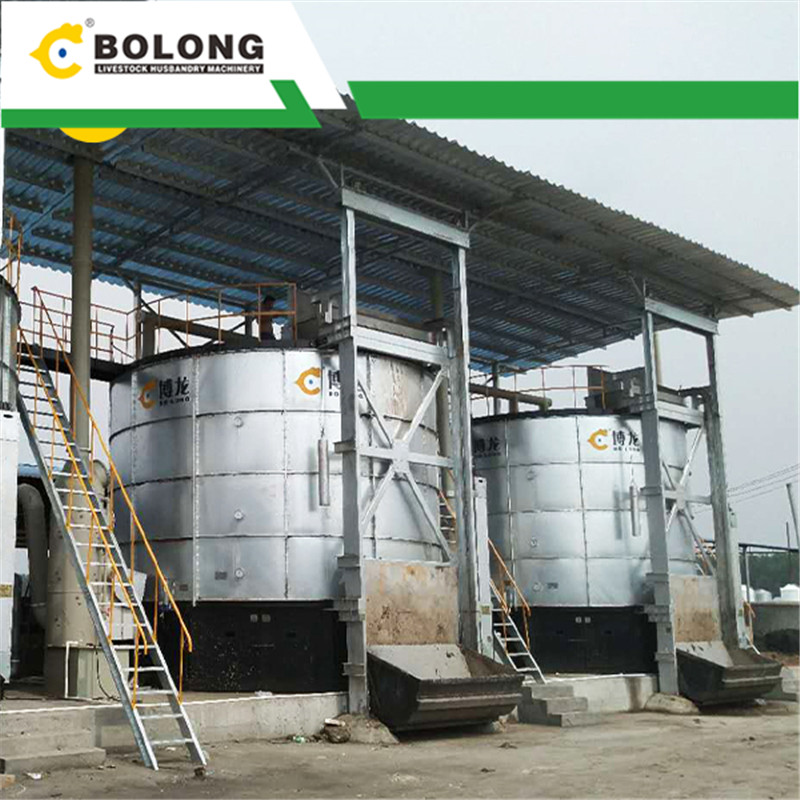

It is designed to provide optimal conditions for the growth and multiplication of microorganisms responsible for the breakdown and conversion of organic materials into

2019/10/23/ · This work aimed to couple lactate production and subsequent chain elongation to decrease chemicals input such as electron donors and hydroxide for pH control in repeated-batch food waste fermentation.

In our 3-part series, Small Changes, Big Impact, we explore the compound effect that minor adjustments can have on boosting sustainability. The third article explores innovative and affordable ways for breweries to boost sustainability by reducing, reusing, and recycling materials they no longer need. Part 1: Reducing and Reusing Ingredients.

2012/10/1/ · Fermentation yielded 670 NL biogas/kg volatile solids (VS) with the CSTR and 550 NL biogas/kg VS with the FBR. The productivities were 3.9 NL biogas/ (L*d) with the CSTR and 3.4 NL biogas/ (L*d) with the FBR. The average methane concentration was approximately 60% for both reactor systems.

ent profile of the food waste fermentation products, reduce odors, and lower the pH. One of them is a widely used commercial inoculant, whereas the other is a laboratory-made compound inocu- manufacturers, microbial inoculum #1 contains Pediococcus lactis and Saccharomyces cerevi-siae, among others, and was purchased from Yi chun Qiang ...

2020/6/25/ · Kenley Fermentation Crock is designed for home use with capacity of 1.3 gallons. Perfect crock for preserving full flavor of kimchi, sauerkraut and other vegetables without artificial additives. Two-piece weighting stones are also included to ensure fermenting vegetables are submerged with brine. View on Amazon.

2023/1/1/ · 1. Introduction. During the sewage treatment process, waste activated sludge (WAS) is produced in large quantities. The treatment and disposal of sludge is one of the biggest challenges facing wastewater treatment plants (WWTPs), which costs up to 60 % of their total operating costs (Wang et al., 2013, Zhu and Chen, 2022).Organic substrates