2022/1/1/ · Generally, the composting fermentation could be distinguished to windrow composting, aerated static composting, and reactor system type according to the fermentation and oxygen supply of composting raw materials in the fermentation process of the composting process. Three types of composting are

The composting machine is a kind of turning equipment used in conjunction with the organic fertilizer fermentation tank.So it is also called a groove type composting machine. In addition, you can use it to ferment organic raw materials in the production process of organic fertilizer, compound fertilizer and other fertilizers.Therefore, groove type

2022/10/24/ · Baraka Poulin. Composting, an aerobic process, relies on microbial bio-oxidation, combining complex organic molecules with oxygen to form carbon dioxide (CO 2 ), water and heat. The first step in designing an aeration system requires understanding how much total oxygen is needed. The reaction in Figure 1 shows the simplified process.

2023/1/1/ · Composting is essentially a process of degradation of organic matter under the action of microorganisms [20].Through the microorganisms’ activities (e.g., bacteria, fungi), organic matter is degraded into a valuable fertilizer that can be used as nutrients for plants and soil amendment [21].The high temperature generated in the composting

2022/2/1/ · The study addresses the embodied environmental implications from the cradle through the organic fertilizer producing site phase of the life cycle. The system limits established for the current research of the solid manure composting system are depicted in Fig. 1. The backdrop system included the manufacturing and gasoline, power, mineral

At commercial scale, only a well-engineered forced aeration system can sustain the process conditions that produce efficient composting. When airflow is insufficient, composting becomes inhibited by a combination of high temperature, low oxygen availability, and often by prolonged low pH. During active composting the airflow required to sustain

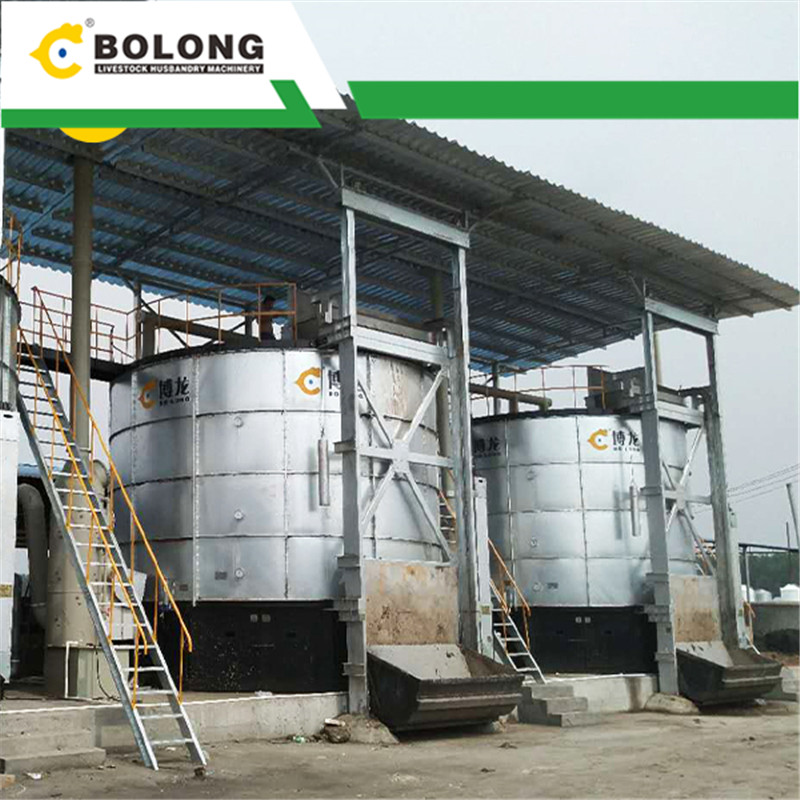

U tilizing the aerobic fermentation technology, our compost machine promote organic waste into bio-organic fertilizer after high temperature decomposition. This process require optimizing control conditions such as temperature, moisture, PH value and C/N ratio.Moreover, you can apply the bio compost processed by our equipment directly to

PDF | On Jan 1, 2019, R ALKARIMIAH published EFFECTS OF TECHNICAL FACTORS TOWARDS ACHIEVING THE THERMOPHILIC TEMPERATURE STAGE IN COMPOSTING PROCESS AND THE BENEFITS OF CLOSED RECTOR SYSTEM

Control moisture content. It is advisable to keep the waste content of cow manure between 45% and 65%. because when the moisture content of cow dung is below 30%, the activity of functional bacteria will be reduced. And when it is higher than

Poultry Manure Composting | Fast Manure Compost | Equipment For small scale poultry farm waste management, we recommend you choose our groove type compost machine. With 2.5-5 m tu. Every 2-3 days during the 14-day fermentation period, drain the juice out of your bokashi fermentation system—this is where that spigot comes in handy. You

Bokashi fermentation is the simplest, least costly, and fastest way to recycle organic waste. It eliminates virtually all greenhouse gases, and sequesters virtually all carbon to

2020/1/1/ · For the through composting system, many enterprises and research institutes have done a lot of research work according to the stacking equipment system and the fermentation process, and have already produced different types of turning machines. The tower fermentation reactor has a basic structure of a closed multilayer fermentation

Carbon and nitrogen are essential elements in the chicken manure composting process. If you want to compost chicken manure quickly, you need to pay attention to the C:N ratio of your raw materials. Generally speaking, when the C:N ratio of raw materials is (25-35):1 the fermentation process will be fastest. 3.

Contents. Horizontal fermentation tank is a kind of fertilizer composting equipment, which is widely used in the production of organic fertilizer. It can complete the harmless treatment process of organic waste in a short time. Such as chicken manure, cattle manure, mushroom waste, Chinese medicine waste, crop straw, etc.

2024/4/1/ · In particular, due to its efficacy in enhancing compost maturation and greenhouse gas emission reduction, SMHC has attracted attention in both research and practical applications (González et al., 2016; Levis and Barlaz, 2011).Fig. 1 c shows the three primary components of the SMHC: the semi-permeable membrane covering system, the …