2024/2/23/ · Fermentation tanks are essential equipment for commercial beverage production facilities. This guide provides breweries, wineries, and other processors with a comprehensive overview of commercial fermentation tank options, considerations for

2024/1/19/ · Beer fermentation is a critical step in brewing where yeast converts sugars into alcohol and carbon dioxide. Proper temperature control, agitation, and yeast health optimization during fermentation ensures high quality, consistent beer output. Special fermentation tanks are used to provide optimum conditions for yeast activity.

2024/3/10/ · Ultimately, the goal of quality control in fermentation is to produce high-quality products with consistent flavor, aroma, and characteristics. 100-gallon fermentation tanks play a crucial role in achieving this goal by providing a controlled environment for fermentation that minimizes variability and ensures reproducibility across batches.

2024/3/4/ · Semi-continuous fermentation. Semi-continuous fermentation of nuclease P1 by Penicillium citrinum was carried out in a 50 L stirring tank when residual sugar, retention volume and air–liquid ratio (v/v) were controlled about 9 g/L, 20% and 1:1, respectively. Figure 2 showed that under semi-continuous fermentation, 6 batches of

The 65L Stainless Steel Conical Fermentation Tank is an excellent choice for home brewing enthusiasts looking for a convenient and versatile fermenter. Pros. Made of

2023/4/17/ · The Brewing Process. Before we explore the ins and outs of 100bbl fermentation tanks, it’s essential to understand the beer brewing process. Here’s a brief overview of the steps involved: Mashing. First and foremost, mashing takes center stage. In this crucial step, brewers mix milled grain with water, creating a mash.

2023/10/18/ · A growing number of science and design scholars and design practitioners have recently embarked on studying fermentation processes to produce alternative materials. The main driver of this trend is the search for a sustainable future by proposing novel alternatives that could substitute or integrate into society’s current

2023/9/22/ · The fermentation tank, along with the brewer’s expertise, plays a crucial role in shaping the flavor, aroma, and quality of the final product, making it a central element in the art of brewing.

11. Conclusion. Brewery fermentation tanks are essential equipment in the beer production process. They provide a controlled environment for yeast to work its magic, converting sugars into alcohol, carbon dioxide, and a plethora of flavors. The design considerations, monitoring systems, and maintenance procedures associated with fermentation

2020/10/13/ · The increase of biomass tended to be stable after 96 h fermentation, which demonstrates the cell growth entered the stationary period. 94 g/L biomass and 2.01 g/L β-carotene concentration were

Fermentation is another anaerobic (non-oxygen-requiring) pathway for breaking down glucose, one that's performed by many types of organisms and cells. In fermentation, the only energy extraction pathway is glycolysis, with one or two extra reactions tacked on at the end. Fermentation and cellular respiration begin the same way, with glycolysis.

2024/4/30/ · Here are some popular suppliers of fermentation tanks to get you started: Speidel: Renowned for their high-quality plastic homebrew and small-scale fermentation tanks. GW Kent: Offers a wide range of fermentation tanks for various applications, from homebrew to large-scale production. Glacier Tanks: Specializes in

2015/1/1/ · Traditional beer fermentation and maturation processes use open fermentation and closed lager tanks. These vessels, previously been considered indispensable, have been replaced during the last decades in many breweries by large-scale fermenters (bioreactors) called cylindroconical vessels (CCVs) or tanks (Figure

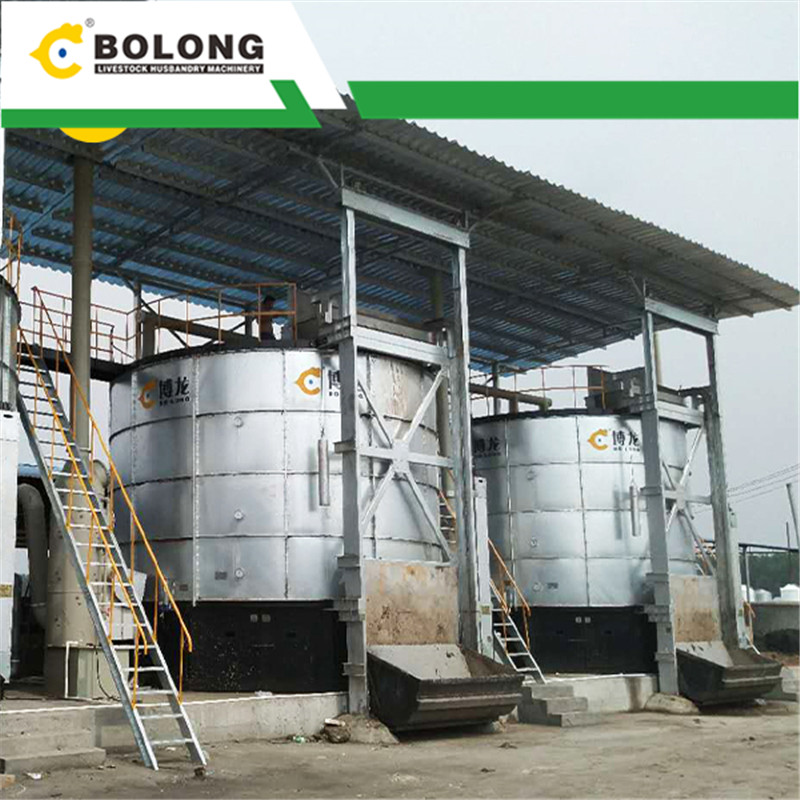

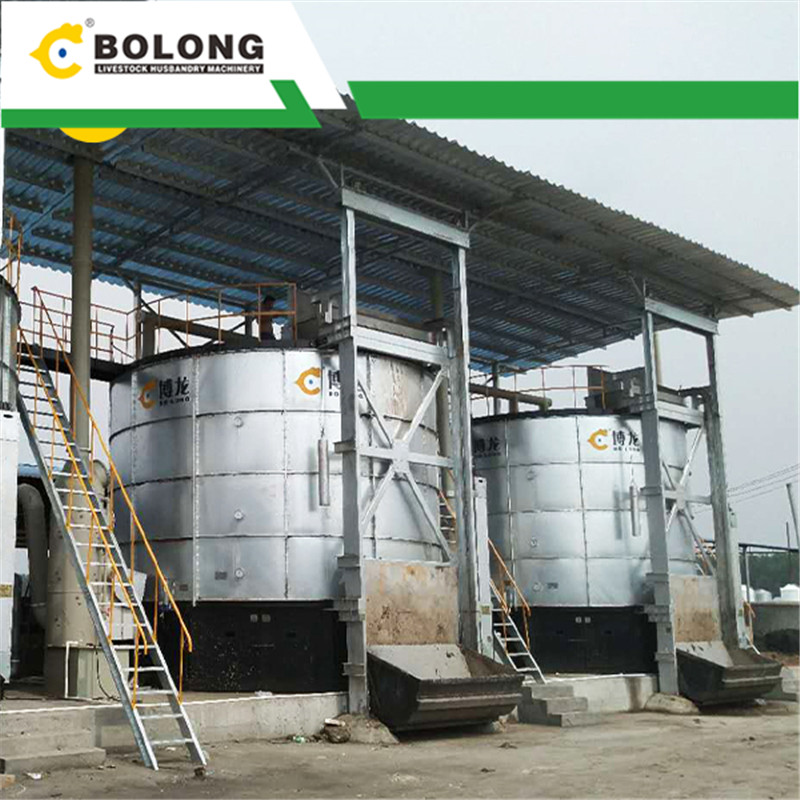

Usage: Compost fermentation for organic fertilizer manure Production capacity: 1-10 tph Matching power: ≥7.5kw Product highlights: High fermentation efficiency and short fermentation cycle Applicable materials: Cattle manure, chicken manure, poultry manure, grass ash, lignite, straw, bean cakes, corn straw etc. Fermentation maturity stage: 4-6

2023/7/24/ · With precise control over fermentation conditions, these tanks ensure consistent product quality, which is vital for establishing a reputable brand and satisfying customer expectations. Cost-Efficiency. Efficient fermentation tanks can lead to reduced production costs by optimizing the use of resources and minimizing wastage. Time-Saving