Anaerobic respiration is a type of cellular respiration where respiration takes place in the absence of oxygen. Fermentation is an anaerobic pathway- a common pathway in the majority of prokaryotes and unicellular eukaryotes. In this process, glucose is partially oxidised to form acids and alcohol. In organisms like yeast, the pyruvic acid

2021/3/1/ · There were 3 cycles fermentation in this experiment, 540 h in all. Compared with the former fermentation in the coupled system without the fixed-bed reactor, the duration was increased by 80 % (Chen et al., 2013a). Every single cycle fermentation was 227 h, 179 h and 113 h, respectively.

2017/4/27/ · Fermentation occurs in certain types of bacteria and fungi that require an oxygen-free environment to live (known as obligate anaerobes), in facultative anaerobes such as yeast, and also in muscle cells when oxygen is in short supply (as in strenuous exercise). The processes of fermentation are valuable to the food and beverage

Bacteria of several gram-positive genera, including Lactobacillus, Leuconostoc, and Streptococcus, are collectively known as the lactic acid bacteria (LAB), and various strains are important in food production.During yogurt and cheese production, the highly acidic environment generated by lactic acid fermentation denatures proteins contained in milk,

2021/11/18/ · Definition and Examples. Fermentation is a biochemical process in organisms that obtains energy from carbohydrates without requiring oxygen. In chemistry and biology, fermentation is a biochemical process that obtains energy from carbohydrates without using oxygen. Many foods come from fermentation, plus the process has

2024/6/20/ · fermentation, chemical process by which molecules such as glucose are broken down anaerobically. More broadly, fermentation is the foaming that occurs during the manufacture of wine and beer, a process at least 10,000 years old. The frothing results from the evolution of carbon dioxide gas, though this was not recognized until the 17th

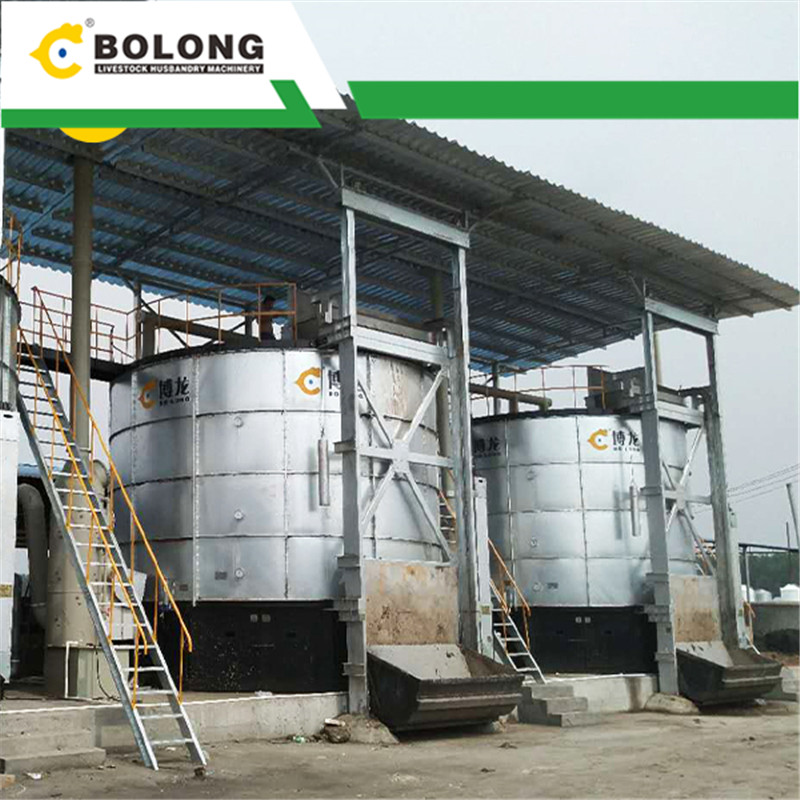

2021/10/30/ · Fertilizer Making Euipment Manufacturer Published Oct 30, 2021 The fermentation cycle is short, the energy consumption is low, and the product quality is stable. 5.

2002/5/25/ · Through this practice of back-slopping, the initial phase of the fermentation process is shortened and the risk of fermentation failure reduced. Repeated use of back-slopping results in selection of the best-adapted strains, some of, which may

2015/11/1/ · This article discusses many of the problems that can arise related to large-scale industrial fermentation vessels (that is, those with a capacity up to 1 million gal) that are increasingly being used for industrial bioprocesses. It also presents recommendations for appropriate CIP and sterilization design for large-scale systems.

2023/9/21/ · Introduction. Saccharomyces cerevisiae, or brewing yeast, is used in a wide range of commercial processes including beverage fermentation, baking, biofuel generation, and pharmaceutical manufacture. The ease of culture and genetic manipulation of S. cerevisiae has also made it one of the most profiled organisms in academic

2024/3/4/ · Liquid fermentation has been adopted by most manufacturers because of its advantages such as short fermentation cycle, high yield and simple separation (Yu et al. 2010). One unit of enzyme activity was defined as the amount of enzyme that produced an increase in the optical density of 1.0 in 1 min at 260 nm. The activity of NP1

2023/9/17/ · The process of alcohol fermentation starts with glucose and ends with the formation of ethanol and carbon dioxide. The production of ethanol from glucose can be represented by the following chemical equation: C6H12O6 (glucose) → 2 C2H5OH (ethanol) + 2 CO2 (carbon dioxide) Alcohol fermentation occurs in two major stages: 1. Glycolysis.

Amylase (E.C.3.2.1.1) is an important enzyme that catalyses the hydrolysis of a-1,4 glycosidic linkage of starch to yield products, maltose, glucose and maltotriose units. Amylase comprises a well characterized group of proteins.

2024/3/1/ · Schematic of Rankine cycle electricity generation (Unit 4 Energy recovery system). The boiler gets 10820 MJ/h from the burner and generates 3480 kg/h steam to the turbine and 354.85 kW of electric energy is produced. Unit 2: Dark-photo fermentation; Unit 3: Methane fermentation and heat exchanger, and Unit 4: Boiler and Turbine